The hum of an electric vehicle isn’t just a sound; it’s the sound of the future roaring onto our roads, completely transforming the automotive landscape we’ve known for decades.

Believe me, as someone who’s spent countless hours under the hood, from tinkering with classic engines to wrestling with the latest hybrids, this shift towards EVs isn’t just a trend—it’s a revolution that demands a whole new skill set from us mechanics.

Suddenly, our trusty wrenches and diagnostic tools are just the beginning; we’re now diving headfirst into the intricate world of high-voltage systems, sophisticated battery management, and complex software diagnostics.

It’s a thrilling, albeit challenging, pivot for anyone in the auto repair business. I’ve seen firsthand how quickly the industry is evolving, and the demand for technicians who truly understand these electrified machines is absolutely exploding.

If you’re like me, always keen to stay ahead of the curve and ensure your skills are as future-proof as possible, then mastering EV repair isn’t just smart—it’s essential.

This isn’t just about fixing cars anymore; it’s about pioneering the future of mobility. Ready to plug into the essential EV repair skills that will supercharge your career?

Let’s dive deep into what it truly takes!

Decoding the High-Voltage Heart: Understanding EV Power Systems

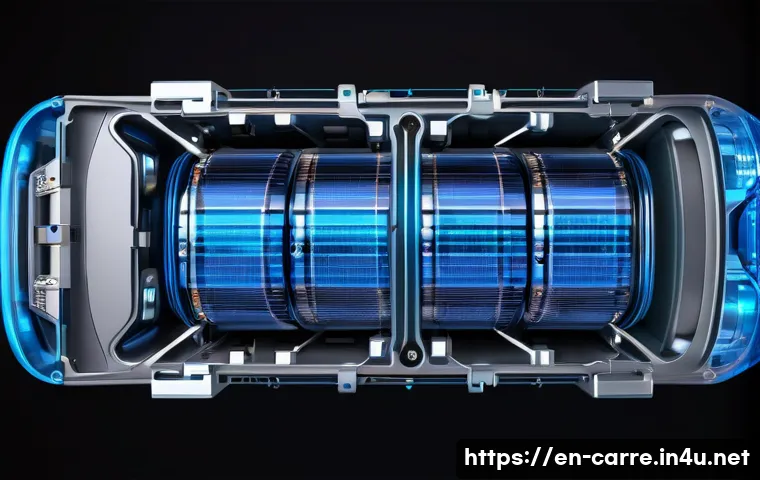

Stepping into the world of electric vehicle repair is like being handed a whole new textbook after years of acing the old one. For me, coming from a background of internal combustion engines, the sheer scale and complexity of EV power systems were a real eye-opener. We’re not just talking about a 12-volt battery here; we’re talking about high-voltage systems that can easily pack a punch of 400V, 800V, or even higher! Believe me, the first time I saw an exposed orange cable, my respect for proper safety protocols went through the roof. It’s a completely different ball game, demanding a deep dive into battery chemistry, inverter functionality, and motor theory. You’ll quickly learn that diagnosing an issue isn’t just about checking spark plugs or fuel injectors; it’s about understanding how energy flows from the battery pack, through the power electronics, and into the electric motors that silently propel these incredible machines. This foundational understanding isn’t just academic; it’s absolutely critical for safe and effective diagnostics and repairs, making it the first truly essential skill you need to master. My own journey into this realm started with a healthy dose of awe and a commitment to rigorous training, because you simply cannot afford to guess when dealing with these powerhouses. It’s all about precision, knowledge, and an unwavering commitment to safety.

The Architecture of Battery Packs

Digging into an EV battery pack feels a lot like exploring a highly advanced, miniature city. It’s not just one big battery, but rather thousands of individual cells meticulously arranged and connected, all working in harmony to provide the vehicle’s power. Each cell is a tiny energy reservoir, and understanding how they’re grouped into modules, and then into the entire pack, is paramount. I remember one of my first encounters with a faulty pack; it wasn’t the entire unit that was bad, but a single module acting up, creating a domino effect on performance. Knowing the different chemistries—lithium-ion, nickel-metal hydride, and the emerging solid-state options—is crucial because each has its own quirks when it comes to charging, discharging, and thermal management. We need to grasp the intricacies of the Battery Management System (BMS), which is the unsung hero, constantly monitoring temperature, voltage, and current to ensure safety and longevity. This isn’t just about swapping out a part; it’s about diagnosing which tiny component within a massive system is causing the ripple, and that requires an intimate knowledge of how these powerhouses are constructed and managed.

Electric Motors and Inverter Systems

When you lift the hood of an EV, or rather, look under the floor in many cases, you won’t find the rumbling engine you’re used to. Instead, you’re greeted by the sleek, often compact, electric motor and its partner in crime, the inverter. The motor itself is a marvel of engineering, converting electrical energy into mechanical motion with incredible efficiency. My experience has shown me that while these motors are generally robust, issues can arise with bearings, windings, or sensors. But it’s the inverter that truly fascinates me. This component is the bridge between the DC power from the battery and the AC power required by the motor, effectively acting as the conductor of the electrical orchestra. Diagnosing inverter problems often involves understanding complex waveforms and power electronics, which is a significant departure from traditional engine diagnostics. You’ll need to familiarize yourself with insulated-gate bipolar transistors (IGBTs) and other semiconductor components that are the workhorses within the inverter. Getting a grip on how these two critical components interact, and how to troubleshoot faults within their sophisticated interplay, is absolutely non-negotiable for any aspiring EV technician.

The Brains of the Operation: Mastering EV Software and Diagnostics

Remember the good old days when a diagnostic scan tool mostly just read engine codes? Well, in the EV world, that scan tool is your new best friend, and it’s gotten a whole lot smarter. EVs are essentially computers on wheels, and understanding their intricate software systems is no longer a luxury—it’s a necessity. I’ve spent countless hours poring over wiring diagrams and service manuals that are now as much about data communication protocols as they are about electrical circuits. Diagnosing an EV fault often starts and ends with software. You might find a seemingly mechanical issue, only to trace it back to a sensor input error or a software glitch. It’s exhilarating, in a way, because it demands a different kind of problem-solving. We’re talking about interpreting data streams, flashing firmware updates, and even coding replacement modules to the vehicle. My own diagnostic approach has evolved dramatically; I now spend a significant amount of time not just looking at physical components, but at what the vehicle’s “brain” is telling me through its complex network of sensors and control units. This mastery of software diagnostics is what truly sets apart an average technician from one who can confidently tackle any EV challenge thrown their way.

Advanced Diagnostic Tools and Procedures

Forget the simple OBD-II scanner; modern EV diagnostics demand a whole arsenal of specialized tools and a mastery of their operation. We’re talking about high-voltage multimeters, insulation testers, thermal imaging cameras to spot hot spots in battery packs, and oscilloscopes to analyze complex waveforms. I’ve personally invested heavily in these tools, and they’ve paid for themselves tenfold by drastically reducing diagnostic time and improving accuracy. It’s not just about having the tools, though; it’s about knowing how to use them effectively. For instance, understanding how to perform an insulation test on a high-voltage system safely and correctly is paramount, as an incorrect procedure could be incredibly dangerous. We also need to get comfortable with manufacturer-specific diagnostic software, which often goes far beyond generic scan tools, allowing deep dives into system parameters, live data, and bidirectional controls. My advice? Get your hands on these tools, practice with them, and understand their limitations. There’s no substitute for hands-on experience when it comes to truly mastering these diagnostic procedures and ensuring you can pinpoint issues with precision and confidence.

Software Updates and Module Programming

The beauty and sometimes the beast of modern EVs lie in their software-defined nature. Unlike older vehicles where a component was simply replaced, in an EV, a “repair” might involve a software update or module reprogramming. I’ve seen situations where a tricky intermittent fault was completely resolved with a simple over-the-air (OTA) update, or after correctly flashing a new firmware version to a control module. This requires not only specific tools but also a meticulous attention to detail and a thorough understanding of the flashing process. A botched update can “brick” an expensive module, so precision and following manufacturer guidelines are critical. We also need to understand how different modules in the vehicle communicate and how programming one might affect another. Sometimes, replacing a component, like a battery management unit or an inverter, isn’t enough; it needs to be “introduced” to the vehicle’s network through a programming sequence. This aspect of EV repair blurs the lines between a traditional mechanic and an IT specialist, requiring a blend of hardware and software expertise that’s truly fascinating to navigate.

Keeping it Cool: Thermal Management for EV Longevity

If there’s one unsung hero in the world of EVs, it’s the thermal management system. When I first started working on these vehicles, I was so focused on the electrical side that I almost underestimated how critical temperature control is for every major component, especially the battery. Think about it: a battery operating too hot or too cold won’t perform optimally, and its lifespan will drastically shorten. I’ve personally seen the damage that can occur when a cooling system fails, leading to reduced range and, in extreme cases, even thermal runaway. It’s not just the battery either; electric motors, inverters, and even charging ports all generate heat that needs to be efficiently dissipated. This means we’re no longer just checking coolant levels for the engine; we’re now dealing with multiple, often distinct, cooling loops and refrigerants, each designed for specific components. Understanding the intricate network of pumps, radiators, chillers, and heat exchangers, and how they all work in concert to maintain optimal operating temperatures, is absolutely fundamental. My experience has taught me that a well-maintained thermal system is key to an EV’s performance, safety, and overall longevity, making its repair and maintenance a truly vital skill.

Battery Thermal Regulation Strategies

The battery is the heart of the EV, and its temperature is absolutely paramount to its health and performance. This isn’t just about keeping it from overheating; it’s also about preventing it from getting too cold, which can severely impact charging efficiency and power delivery. I’ve worked on EVs with active liquid cooling systems, where coolant circulates through channels embedded within the battery pack, and others with air cooling. Then there are systems that use refrigerants, similar to an air conditioning system, to precisely control temperatures. Diagnosing issues within these systems requires a different mindset. It’s about checking coolant pumps, radiator fans dedicated to the battery, temperature sensors, and the control algorithms that govern their operation. You might find a fault code pointing to reduced battery performance, only to discover a clogged filter or a failing coolant pump in the thermal management system. Understanding these diverse strategies, and knowing how to troubleshoot each one, is crucial for ensuring the battery operates within its ideal temperature window, which in turn maximizes its lifespan and the vehicle’s range.

Motor and Power Electronics Cooling

It’s easy to focus solely on battery cooling, but the electric motor and the power electronics, particularly the inverter, also generate significant heat under load. These components are designed for high efficiency, but no electrical conversion is 100% efficient, and the wasted energy manifests as heat. Just like an engine, if these components overheat, their performance degrades, and their lifespan is compromised. I’ve encountered situations where a vehicle was going into “limp mode” during aggressive driving, and the root cause wasn’t the battery, but an overheating inverter. This often means separate cooling circuits, sometimes sharing components with the cabin HVAC system, but always precisely managed. We need to be adept at checking flow rates in these cooling lines, inspecting heat sinks, and diagnosing issues with the dedicated pumps and fans that keep these vital components at their optimal operating temperatures. Ignoring these secondary cooling systems would be a huge oversight, as their proper functioning is just as critical to the overall reliability and performance of an electric vehicle as the battery’s thermal health.

Beyond the Battery: Charging Systems and Infrastructure Know-How

It’s one thing to fix the car itself, but an EV isn’t much good if it can’t charge, right? My journey into EV repair quickly taught me that understanding charging systems isn’t just about the port on the car; it’s about the entire ecosystem from the grid to the battery. We’re talking about Level 1, Level 2, and DC fast charging, each with its own specific protocols, power levels, and potential points of failure. I’ve had customers bring in vehicles convinced there’s a battery issue, only to find the problem was with their home charging setup, or even a faulty public charging station. This requires us as technicians to have a broader understanding of electrical infrastructure and grid connectivity. We need to be able to diagnose issues within the vehicle’s onboard charger, the charging port itself, and even understand the communication protocols that allow the vehicle to “talk” to the charging equipment. It’s a field that’s constantly evolving, with new charging technologies and standards emerging regularly, so staying updated is absolutely essential. From understanding voltage conversion to troubleshooting ground faults, this aspect of EV repair demands a comprehensive electrical knowledge that extends beyond the vehicle itself, bridging the gap between automotive and electrical engineering.

Onboard Chargers and Charging Port Diagnostics

The onboard charger (OBC) is a fascinating piece of equipment, effectively converting the AC power from a standard wall outlet or Level 2 charger into the DC power that the battery can store. When problems arise, the OBC is often a prime suspect. I’ve spent hours meticulously testing these units, often finding issues with internal rectifiers or control circuits. Then there’s the charging port itself, which, much like a gas tank filler, takes a lot of abuse. I’ve repaired countless ports with bent pins, corrosion, or damaged locking mechanisms from everyday wear and tear. Diagnosing these requires a combination of visual inspection, continuity testing, and using advanced scan tools to monitor communication between the vehicle and the charging equipment. It’s also important to understand the different types of charging ports—Type 1, Type 2, CCS, CHAdeMO—and how they communicate. A thorough understanding of the power flow and communication signals within the OBC and charging port is essential for quickly identifying and rectifying charging-related issues, ensuring the vehicle can reliably top up its energy reserves.

Understanding Charging Standards and Public Infrastructure

As EV owners increasingly rely on public charging, technicians need to understand the nuances of the charging infrastructure. I’ve fielded many calls from frustrated owners whose car wouldn’t charge at a specific public station, only to discover it was an incompatibility issue or a fault with the station itself, not the vehicle. This means having a basic grasp of charging standards like J1772 for AC charging, and CCS or CHAdeMO for DC fast charging. It’s also about understanding the communication protocols that ensure a safe and efficient charge, such as ISO 15118 for “Plug & Charge” capabilities. We need to be able to advise customers on how to troubleshoot common charging issues outside of the shop, and even identify when a charging station itself might be the problem. My advice is to explore local charging networks, understand how they operate, and familiarize yourself with the common charging hardware available. This broader knowledge base not only helps us fix cars but also positions us as trusted advisors to EV owners navigating the evolving landscape of electric mobility.

Safety First, Always: Navigating the Risks of EV Repair

When you’re dealing with hundreds of volts and significant amperage, safety isn’t just a guideline; it’s the absolute foundation of everything you do. Coming from traditional automotive repair, where the biggest electrical shock risk was usually a minor jolt from a spark plug, the high-voltage systems in EVs command an entirely different level of respect. I’ve seen firsthand how a moment of inattention or a lapse in protocol could lead to severe injury, or worse. This isn’t about fear-mongering; it’s about being incredibly diligent and methodical. Personal protective equipment (PPE) like insulated gloves, face shields, and specialized tools are non-negotiable. More importantly, understanding lockout/tagout procedures, verifying zero voltage, and working with a safety buddy are paramount. Every time I approach a high-voltage component, I go through a mental checklist, ensuring every safety step is meticulously followed. It’s not just for my own protection, but also for the safety of my team and the integrity of the vehicle. Mastering EV repair means first mastering EV safety, because without it, nothing else matters. My commitment to safety is unwavering, and it’s a mindset I strive to instill in everyone working with these powerful machines.

High-Voltage Disconnection and Lockout Procedures

The very first, and arguably most critical, step before any high-voltage work begins is safely de-energizing the system. This isn’t as simple as pulling a fuse. EVs typically have a complex high-voltage interlock system designed to prevent accidental contact with live circuits. We need to know how to properly disable the high-voltage system, often involving specific service disconnects, removal of fuses, and sometimes waiting a predetermined amount of time for capacitors to discharge. I’ve always emphasized the importance of double-checking—and triple-checking—voltage readings with a certified high-voltage multimeter *after* the system has supposedly been de-energized. Lockout/tagout procedures are non-negotiable; this means physically securing the disconnected components and placing a tag to ensure no one inadvertently re-energizes the system while you’re working. Failing to follow these procedures exactly could have catastrophic consequences, which is why I view mastery of high-voltage disconnection as the cornerstone of safe EV repair practices. It’s a precise dance of methodical steps, each one critical to preventing harm.

Personal Protective Equipment (PPE) and Workshop Safety

Beyond the procedural aspects, having and correctly using the right Personal Protective Equipment (PPE) is absolutely essential when working on EVs. This includes insulated gloves rated for the voltage levels you’ll encounter, arc-flash rated face shields and clothing, and dielectric boots. I’ve seen workshops that cut corners on PPE, and it’s a dangerous game to play. These aren’t just recommendations; they are vital layers of protection. Furthermore, the workshop itself needs to be set up with safety in mind. This means having designated high-voltage work areas, non-conductive floor mats, readily accessible emergency shut-off switches, and proper signage to warn others of potential hazards. I also make sure we have appropriate fire extinguishers (Class C for electrical fires) on hand. My experience has taught me that a safe workshop environment, combined with strict adherence to PPE protocols, creates a culture where technicians can work confidently and without unnecessary risk. It’s about empowering everyone to do their job effectively, knowing they are protected by the best available safety measures.

Tools of the Trade: Equipping Your Workshop for the Electric Age

Just as you wouldn’t attempt to rebuild an engine with only a screwdriver, you can’t properly diagnose or repair an EV without a specialized set of tools. When I first started transitioning my shop, I quickly realized that many of my trusty old tools simply wouldn’t cut it. The investment was substantial, but absolutely necessary, and it’s paid off in spades. We’re talking about everything from insulated hand tools—wrenches, screwdrivers, pliers—that protect against high voltage, to advanced diagnostic scanners capable of communicating with complex EV control modules. Then there are specialty lifting equipment capable of handling the immense weight of battery packs, and even dedicated battery removal and installation platforms. My personal experience has been that having the right tool for the job not only makes the work safer but also dramatically increases efficiency and accuracy. Trying to adapt conventional tools for EV work is not only dangerous but often leads to frustration and potential damage. Equipping your workshop for the electric age isn’t just about buying new shiny objects; it’s about strategically investing in the specialized equipment that empowers you to perform safe, accurate, and profitable EV repairs.

Insulated Hand Tools and High-Voltage Specific Equipment

One of the most immediate and critical changes to my toolbox when I started working on EVs was the introduction of insulated hand tools. These aren’t just regular tools with a bit of rubber coating; they are specifically designed and tested to protect against electrical shock, often rated up to 1000V. I’ve personally experienced the peace of mind that comes with knowing your tools are an extra layer of defense when working near high-voltage circuits. Beyond basic hand tools, we’re now using specialized high-voltage multimeters with specific safety ratings, insulation testers to check for current leakage, and even dedicated battery module lifting devices. Another essential is a certified arc-flash suit, which I hope to never have to use, but its presence is a testament to the potential dangers. The precision and safety provided by these tools are non-negotiable. I can’t stress enough how important it is to purchase high-quality, properly rated insulated tools from reputable suppliers. Skimping here is a false economy that could have severe consequences, making this a foundational aspect of equipping any EV repair facility for safe and effective service.

Advanced Diagnostic Scanners and Software

While insulated tools protect our bodies, advanced diagnostic scanners and software are the eyes and ears into the EV’s intricate electronic brain. Gone are the days when a generic OBD-II scanner could give you all the information you needed. Modern EVs require sophisticated scan tools capable of deep-level communication with battery management systems, motor control units, and power electronics. I’ve invested in several manufacturer-specific diagnostic platforms, and while costly, they provide unparalleled access to fault codes, live data, bidirectional controls, and critical service functions like battery module balancing or inverter recalibration. These tools allow me to see exactly what each sensor is reporting, understand the vehicle’s internal communication network, and perform necessary software updates or module programming. Without these advanced diagnostic capabilities, you’re essentially flying blind, unable to accurately pinpoint complex electronic faults. My personal advice is to prioritize these tools as much as your physical ones; they are equally vital for performing efficient, accurate, and comprehensive EV repairs in today’s technologically advanced automotive landscape.

| Component Type | Internal Combustion Engine (ICE) Vehicle | Electric Vehicle (EV) | Key Repair Considerations |

|---|---|---|---|

| Power Source | Gasoline/Diesel Engine | High-Voltage Battery Pack | ICE: Mechanical wear, fluid leaks, exhaust issues. EV: Cell degradation, thermal management, software faults, high-voltage safety. |

| Propulsion Unit | Transmission, Drive Shafts, Differential | Electric Motor(s), Power Inverter | ICE: Gear wear, fluid changes, clutch replacement. EV: Motor winding checks, inverter diagnostics, sensor calibration, rare earth element considerations. |

| Fuel/Energy Delivery | Fuel Pump, Fuel Lines, Injectors | Onboard Charger, Charging Port, BMS | ICE: Clogs, leaks, pressure regulation. EV: Communication protocols, voltage conversion, ground faults, thermal issues during charging. |

| Thermal Management | Engine Radiator, Water Pump, Thermostat | Multiple Cooling Loops (Battery, Motor, Inverter), Chillers, Refrigerants | ICE: Coolant leaks, pump failure, thermostat replacement. EV: Complex fluid circuits, refrigerant leaks, electronic control of cooling components. |

| Diagnostic System | Basic OBD-II Scan Tools, Powertrain Control Module (PCM) | Advanced Manufacturer-Specific Scanners, Battery Management System (BMS), Motor Control Unit (MCU), Vehicle Control Unit (VCU) | ICE: Emission-related codes, sensor faults. EV: High-voltage system faults, cell monitoring, software updates, inter-module communication issues. |

Hands-On Learning: Practical Training and Certification Pathways

Let’s be real: you can read all the textbooks and watch all the online videos in the world, but nothing, and I mean *nothing*, compares to getting your hands dirty with an actual EV. My journey into becoming an EV expert was a blend of formal training and countless hours of practical, hands-on work. It’s the difference between knowing the theory of high-voltage disconnection and actually performing it safely, confidently, and repeatedly. This industry is moving at lightning speed, and continuous learning isn’t just a buzzword; it’s an absolute necessity. I’ve personally pursued multiple certifications, not just to boost my credentials, but because each course offered invaluable practical experience and exposed me to real-world scenarios that no simulation could fully replicate. The investment in time and money for quality training is one of the best decisions I’ve ever made for my career, allowing me to stay ahead of the curve and confidently tackle the latest EV technologies. If you’re serious about mastering EV repair, then committing to comprehensive, hands-on training and recognized certifications is your expressway to expertise and a truly future-proof career.

Industry-Recognized EV Certifications

When it comes to proving your mettle in EV repair, industry certifications are your golden ticket. They’re not just fancy pieces of paper; they demonstrate that you’ve met rigorous standards of knowledge and practical skill. I’ve personally found certifications from organizations like ASE (Automotive Service Excellence) in the U.S. for Hybrid/Electric Vehicle Specialist (L3) to be incredibly valuable. There are also manufacturer-specific training programs, often offered by brands like Tesla, GM, Ford, or Hyundai, which are absolutely essential if you plan to specialize in a particular make. These programs dive deep into their specific architectures, diagnostic tools, and repair methodologies. Getting certified isn’t just about passing a test; it usually involves extensive hands-on training that simulates real-world repair scenarios, allowing you to build confidence and proficiency in a safe, controlled environment. My advice? Research the certifications that align with your career goals and location, and commit to achieving them. They’ll open doors, build trust with customers, and solidify your reputation as a true EV expert.

Apprenticeships and Practical Workshop Experience

While certifications provide the foundational knowledge and theoretical understanding, an apprenticeship or extensive practical experience in a dedicated EV repair shop is where theory truly meets reality. This is where you learn the nuances that no textbook can teach, like the subtle feel of a healthy high-voltage connector or the specific sound of a struggling inverter. I firmly believe that shadowing experienced technicians, asking a million questions, and getting hands-on with actual customer vehicles under supervision is paramount. My own learning curve accelerated dramatically once I was regularly working on EVs, diagnosing real problems, and performing actual repairs. It’s during these practical experiences that you refine your diagnostic intuition, troubleshoot unexpected issues, and truly embed safety protocols into your muscle memory. If you can find an opportunity to apprentice or work in a shop that specializes in EVs, jump on it. The blend of formal training and robust practical experience creates a well-rounded technician who isn’t just knowledgeable, but truly capable and confident in the rapidly evolving world of electric vehicle service.

Wrapping Up Our Electric Journey

Whew, what an electrifying deep dive we’ve had into the world of EV repair! It’s been quite a journey, hasn’t it? From demystifying those high-voltage systems that initially felt like something out of a sci-fi movie, to wrestling with intricate software diagnostics, and even appreciating the subtle art of thermal management – it’s clear that electric vehicles are a different breed. My hope in sharing these insights, born from countless hours of hands-on experience and continuous learning, is to give you a clearer, more confident roadmap. This isn’t just about fixing cars anymore; it’s about pioneering the future of mobility, one precise, safe repair at a time. The transition can feel daunting, but with the right knowledge, the right tools, and an unwavering commitment to safety, you’re not just ready for the electric age – you’re leading it.

Handy Tips You’ll Be Glad to Know

1. Always treat high-voltage systems with the utmost respect; safety protocols are non-negotiable for your well-being and the vehicle’s integrity.

2. Embrace continuous learning; the EV landscape is evolving rapidly, and staying updated with new technologies and repair techniques is paramount.

3. Invest wisely in specialized tools, especially insulated hand tools and advanced diagnostic scanners – they are crucial for both safety and efficiency.

4. Don’t overlook thermal management; understanding how to keep batteries, motors, and inverters cool is key to an EV’s performance and longevity.

5. Develop strong software diagnostic skills; EVs are computers on wheels, and often, the fix is in the code or a firmware update.

Key Takeaways for Your EV Repair Journey

Ultimately, navigating the world of EV repair boils down to a few core principles that I’ve learned through trial and error: absolute dedication to safety above all else, a deep commitment to mastering complex electrical and software systems, and the foresight to continuously invest in specialized training and the right equipment. The shift to electric vehicles isn’t just a trend; it’s a fundamental change in automotive engineering that demands a new kind of expertise. By focusing on these critical areas, you’re not just preparing for the future; you’re actively shaping it, ensuring you remain an indispensable part of the automotive industry’s most exciting chapter yet. Stay sharp, stay safe, and keep those electrons flowing!

Frequently Asked Questions (FAQ) 📖

Q: Why is it so crucial for mechanics to learn EV repair skills right now?

A: Believe me, I’ve watched this industry evolve faster than a drag racer off the line, and the shift to EVs isn’t just a gentle curve—it’s a sharp turn that’s reshaping everything we know.

From where I’m standing, if you’re not getting ahead of the curve with EV knowledge, you’re frankly risking being left behind. The numbers don’t lie: electric vehicles are becoming a mainstream choice, and with more of them on the road, the demand for skilled technicians who actually know how to fix them is absolutely skyrocketing.

It’s not just about future-proofing your career; it’s about making sure you’re ready for the present. I’ve seen countless shops scrambling to find qualified people, and those who’ve taken the leap to master EV repair?

They’re the ones with packed schedules and a reputation for being the go-to experts. This isn’t just a trend; it’s a fundamental change in how we drive, and how we fix cars.

Q: What specific new skills do I actually need to master to repair electric vehicles effectively?

A: It’s not just about turning wrenches anymore, my friends. We’re talking about a whole new ball game that’s equal parts exciting and challenging. First off, high-voltage systems are paramount.

Forget everything you knew about 12-volt batteries; these systems are incredibly powerful and demand a completely different level of respect and safety training.

Then there’s the intricate world of battery management systems (BMS) – understanding how these batteries operate, charge, and discharge is crucial, as is diagnosing any issues within them.

Software diagnostics, too, are no longer a side note; they’re at the very heart of EV repair. You’ll be connecting to vehicles, reading fault codes that relate to everything from motor control to thermal management, and performing software updates.

Plus, let’s not forget regenerative braking systems, electric motors, and power electronics. It’s a steep learning curve, for sure, but mastering these areas means you’re not just a mechanic; you’re an EV specialist, ready for anything these futuristic machines throw your way.

Q: How will mastering EV repair truly impact my career and job prospects in the long run?

A: Let me tell you, from what I’m seeing on the ground, this isn’t just a bump in your paycheque; it’s a launchpad for your entire career! Seriously, the demand for EV technicians is absolutely off the charts, and it’s only going to grow.

When you’re one of the few who truly understands the ins and outs of electric vehicles, you immediately become a highly sought-after commodity. This translates directly into better job security, often higher earning potential, and the kind of professional respect that comes with being at the forefront of automotive technology.

I’ve seen technicians who embraced this early on now training others, opening their own specialized shops, and basically becoming local legends. It’s not just about fixing cars; it’s about pioneering the future of mobility and placing yourself in an incredibly strong position for years to come.

If you’re looking to make your career recession-proof and exciting, diving into EV repair is, without a doubt, one of the smartest moves you can make right now.